Kids aquafresh… who knew a simple everyday product would gum us up for 11 and a half hours?!

Most loads go smooth and uneventful, which is exactly how we like them. Every now and then that one load comes along that is just plagued with problems. This was that load.

Our tractor and trailer is heavier than most others on the road. We have a super duty ‘moose’ bumper which adds a significant amount of weight to the front. Our trailer is double insulated which adds weight and makes the interior narrower than the typical trailer.

Our axle and steer tires are heavy duty and rated for 13, 200 lbs. The fifth wheel plate is adjustable so we have it all the way back to pull the extra weight off our steer tires. This in turn puts more weight onto our drive tires. The most weight we are allowed to run with on our drive tires is 34,000 lbs. The trailer tandem are also adjustable and can only carry 34,000 lbs.

This is all important when loading the trailer. The placement of the pallets is important to the weight distribution and remaining legal for each axle even if the total weight falls under the max allowed of 80,000 lbs.

So, how did our day get so stretched out? It went like this…

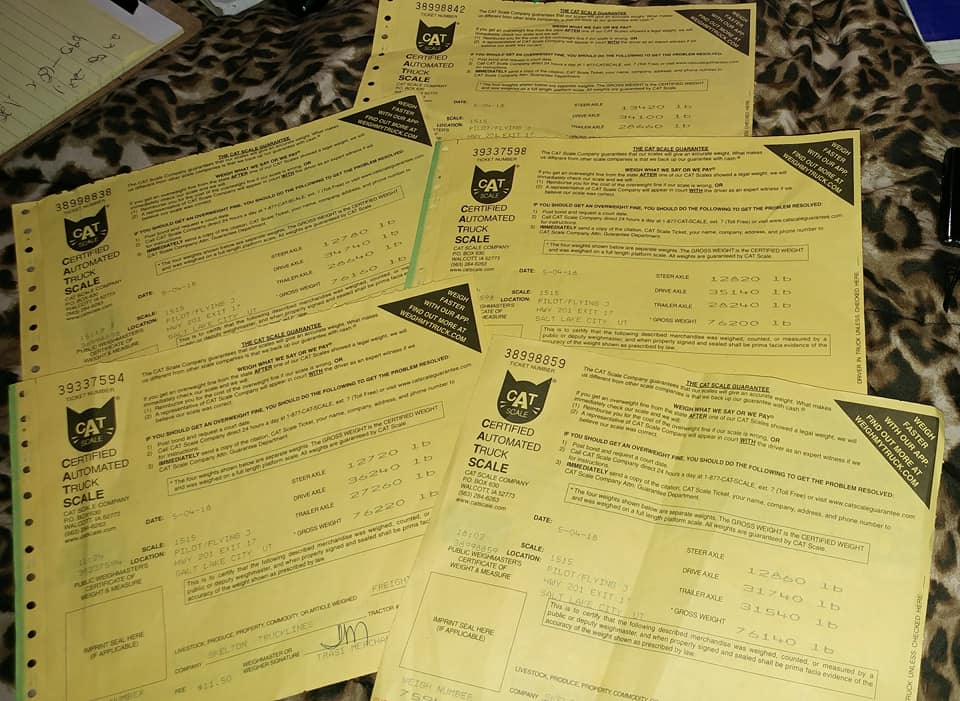

Our appointment, which we were early for, was for 0800. What typically takes less than two hours took nearly four. If the weight of the load is over 30,000 lbs we always drive to the nearest truck scale to get weighed. These scales give the total weight as well as break it down per axle. The nearest scales were 15 miles north in the heart of Salt Lake City. Getting there wasn’t too bad, medium traffic with construction made our travel time about 30 minutes. We were under the total weight allowed but we were over the allowed weight on the drive tires. We adjusted our trailer tandems the furthest we could in order to take as much weight off our drives. We re-weighed and were still over but it gave us the information we needed to go back to the shipper to have the load re-worked.

The traffic started getting heavy when we left the scales, which is puzzling because it was still the middle of the afternoon. Once back at the shipper we explained the situation and how to solve the problem and make our axle weights. Surprisingly, we were told that this is how they are told they have to place the pallets. After some discussion and waiting for them to finish loading another truck they had us back into the dock and agreed to move a couple of pallets to the rear. This wasn’t all that we requested but all they were willing to compromise. So, another hour plus gone and back to the scales we go. Yea, you guessed it, in even heavier traffic. At the scale, still too heavy on the drives. We moved our fifth wheel plate taking weight off the drives and placing it on the steers. This put the front axle weight over the max allowed. Back across the scales to get another set of numbers to take back to the shipper. Now the traffic is to the stop and go speed the entire way back. Finally they agreed to do exactly as we requested the first time. Each time they re-worked this load they had to take each pallet off, run it back to their cooler until they got to the the ones the needed to pull to add to the back. Then back to the cooler, one at a time to load back onto the trailer. Once they completed this task for the third time we left and drove back to the scales. Now the traffic north was also at the stop and go speed. We had gone across the scale so many times compared to what is normal the attendant gave us our last two weighs free. This last time all axles were within legal weights! Eleven and a half hours later, 5 scale tickets, and more time than we would have liked driving in Salt Lake City of which we should have been over 650 miles further east, we finally we able to start that direction!

Thank goodness days like this are not normal.

The bright side, we had beautiful weather with views that were easy on the eyes and creativity on the overhead highway sign.